From inside (document excerpt):

LSB LSB Large Square Balers 870, 890, 1270 and 1290 S Q UA R E B A L I N G T E C H N O LO GY AT I T S B ES T! LSB 870, 890, 1270 AND 1290 KUHN BALERS The ability to produce top quality bales in all crop conditions sets KUHN large square balers apart from all others. Every step in the baling process has to be coordinated and optimized, accounting for crop conditions, field conditions and weather, as well as crop handling and storage.

Agricultural Equipment Manual Free Download. Lawn Mowers Specs. Power Harvesting Machinery Free Specification Download PDF.

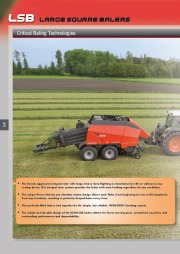

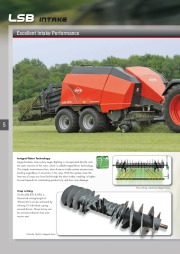

Perfectly-shaped bales, combined with high output and outstanding durability, ensure the KUHN baler will be a profitable investment. Field performance, bale quality and bale density are fundamental to the profitability of every baling operation. Every minute counts when weather conditions are uncertain. The unique innovations on the KUHN balers make a real difference in field performance. KUHN offers the most efficient and versatile range of balers available for the market. KUHN balers are not only designed to produce top quality bales but are also built for unmatched reliability. KUHN offers solutions for Large Square Baling while meeting your requirements in terms of: Cost reductions Good practices www.kuhn.com Comfort Quality of life Proximity Advice Peace of mind Services LSB LARGE SQUARE BALERS Critical Baling Technologies 3 · The forced, aggressive integral rotor with large, heavy-duty flighting is manufactured with or without a crop cutting device. This integral rotor system provides the baler with even feeding regardless of crop conditions. The unique Power Density pre-chamber intake design allows each flake, from beginning to end, to fill completely from top to bottom, resulting in perfectly-shaped bales every time. This perfectly-filled bale is tied together by the simple, but reliable, TWIN-STEP® Knotting system. The simple and durable design of the KUHN LSB balers allows for fewer moving parts, unmatched crop flow, and outstanding performance and dependability. v www.kuhn.com Key Features Simple technology that produces rock-hard, super-dense, well-shaped bales. Integral rotor – The aggressive design provides maximum efficiency, with high-performance throughput in all crop conditions. Cam clutch protection – Main intake functions are protected by a series of convenient clutches instead of shear bolts. Power Density – This pre-chamber design allows the baler to adapt to changing windrows for uniform flakes and a consistent bale. Plunger – Extreme-duty, 150 mm (6 in.) plunger bearings and hardened rails are standard on all KUHN LSB models. TWIN-STEP® Knotting – The patented system instantly releases the tension on the twine, providing increased reliability and trouble-free knotting. ISOBUS – This feature is standard on the LSB and the tractor’s existing ISOBUS monitor can be used if available. LSB 870 2×3 LSB 890 3×3 4 70 x 80 cm 80 x 80 cm 90 x 80 cm LSB 1270 2×4 LSB 1290 3×4 70 x 120 cm 80 x 120 cm 90 x 120 cm LSB INTAKE Excellent Intake Performance BALE TRACK 5 Integral Rotor Technology Large-diameter, heavy-duty auger flighting is incorporated directly onto the outer sections of the rotor, which is called Integral Rotor Technology. This simple, maintenance-free, short-distance intake system ensures even feeding regardless of variations in the crop. With this system, even the heaviest of crops are force-fed through the short intake, resulting in higher forward speeds for outstanding productivity and less crop damage. Non-cutting, OptiFeed Integral Rotor Crop cutting On the LSB 870 & 890, a theoretical cutting length of 70mm (2¾ “) can be achieved by utilizing 10 individual, springsecured knives. These knives can be activated directly from your tractor seat. 10-knife, OptiCut Integral Rotor www.kuhn.com OmniCut OmniCut In place of the standard non-cutting integral rotor, KUHN offers the OmniCut Integral Rotor on LSB 1270 & 1290 models. This largediameter, V-shaped intake rotor takes the crop directly from the pickup, cutting and spreading it evenly toward the pre-chamber. Knife select ….. …

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 1 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 1 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 2 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 2 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 3 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 3 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 4 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 4 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 5 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 5 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 6 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 6 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 7 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 7 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 8 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 8 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 9 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 9 of 16 Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 10 of 16

Kuhn LSB LSB Large Square Balers 870 890 1270 1290 Agricultural Catalog - 10 of 16