From inside (document excerpt):

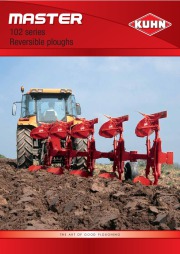

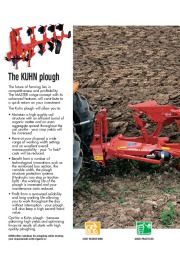

MASTER 102 series Reversible ploughs THE ART OF GOOD PLOUGHING The KUHN plough The future of farming lies in competitiveness and profitability. The MASTER range concept with its advanced features will contribute to a quick return on your investment. The Kuhn plough will allow you to: · Maintain a high quality soil structure with an efficient burial of organic matter and an even aggregate spread throughout the soil profile – your crop yields will be increased.

Agricultural Equipment Manual Free Download. Lawn Mowers Specs. Power Harvesting Machinery Free Specification Download PDF.

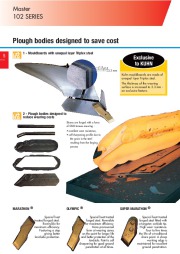

· Have at your disposal a wide range of working width settings and an excellent overall manoeuvrability – your “in field ” costs will be reduced. · Benefit from a number of technological innovations such as the reinforced box section, the variable width, the plough structure protection systems (Hydraulic non-stop or traction bolt) – the working life of the plough is increased and your maintenance costs reduced. · Profit from a renowned reliability and long working life allowing you to work throughout the day without interruption – your plough will also keep a high second-hand value. Opt for a Kuhn plough – because obtaining high yields and optimising financial results all starts with high quality ploughing. KUHN offers solutions for ploughing while meeting your requirements with regards to : COST REDUCTIONS GOOD PRACTICES COMFORT – QUALITY LIFE PROXIMITY – ADVICES PEACE OF MIND – SERVICES Master 102 SERIES High strength headstocks and frames 3 Robust, reliable and economic ploughs. – Large trash burial capacity, the traction bolt models can be adjusted from 70 cm to 75 cm underbeam clearance. – Independently mounted skimmers for quick and easy adjustment. – Depth control wheel in line with frame. – Transport wheel fitted with suspension. 2 · 1 3 SPECIFICATION Number of bodies Maximum horsepower per body (kW/hp) Traction bolt dafety Non-Stop Hydraulic system Working width Clearances (cm) Beam section (mm) Under beam Point to point MASTER 102 Monobloc Headstock 3 to 5 on T – 2 to 4 on NSH 21/29 yes yes 14 ” and 16 ” 70 and 75 on T – 70 on NSH 90 100 x100 on 2E/3T and NSH and 3E/4T 120 x120 on 3E/4T NSH and 4E/5T Quick-hitch cross-shaft, with adjustable height on model 4E/5T. Turnover shaft in treated alloy diameter : – 70 mm on 2E/3T – 85 mm on 2E/3NSH and 3E/4T – 90 mm on 3E/4NSH – 105 mm on 4E/5T Simple adjustment of levelling by screw stops. Built-in toolbox in headstock for models 3E/4NSH and 4E/5T. Plough leg safety in all conditions Depth and transport wheels. The 500 mm steel, or 600 mm rubber tyre wheel follows any change of ploughing width. It features simple depth adjustment by screw adjuster, with the possibility of setting left and right sides differently.

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 1 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 1 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 2 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 2 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 3 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 3 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 4 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 4 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 5 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 5 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 6 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 6 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 7 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 7 of 8 Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 8 of 8

Kuhn MASTER 102 Series Reversible Ploughs Agricultural Catalog - 8 of 8