From inside (document excerpt):

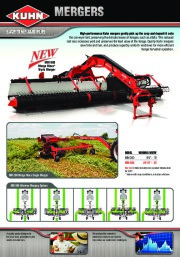

lower case thinner border High-performance Kuhn mergers gently pick up the crop and deposit it onto the conveyor belt, preserving the delicate leaves of forages, such as alfalfa. This reduced leaf loss increases yield and preserves the feed value of the forage. Quality Kuhn mergers save time and fuel, and produce superbly uniform windrows for more efficient forage harvester operation. MM 900 Merge Maxx® Triple Merger Upper case Garamond MODEL MM 300 MM 900 WORKING WIDTH* 9’6 ” 18′ 29’10 ” 35′ MM 300 Merge Maxx Single Merger MM 900 Windrow Merging Options Red text in table denotes new product introduction for 2011 * Varies with crop conditions, includes windrow A quality product begins its life as an idea, generated by the needs of customers.

We analyze the market to determine what we can build to help solve our customers’ challenges. original Quality Kuhn rotary rakes help produce premium hay. Long, flexible tines touch the crop just once, lifting and depositing it neatly into the windrow. This gentle raking action ensures that the leaves remain intact. The fluffy, well-formed windrows promote faster drying, enabling producers to harvest crops at their peak nutritional value with less reliance on the weather. lower case thinner border GA 9032 Twin-Rotor, Side-Delivery Rake lower case thinner border lower case Garamond Upper case Garamond Upper case Garamond The Generation III Rotor is standard on select new models for 2011 GA 4220 TH Single-Rotor, Side-Delivery Rake MODEL** WORKING WIDTH* GA 300/3200/3201 10’6 ” GA 4121 13’5 ” GA 4220/4221 13’5 ” GA 4321 13’9 ” GA 4521 14’9 ” GA 6002 11’6 ” 19′ MODEL WORKING WIDTH* GA 6501 17’9 ” 21′ *** 12’6 ” 21’4 ” GA 6622 GA 7501 22’6 ” 24’5 ” GA 7922*** 14’1 ” 25’7 ” GA 7932 14’1 “ 25’1 ” GA 8020 25’7 ” GA 8121 Twin-Rotor, Center-Delivery Rake MODEL** WORKING WIDTH* GA 8121*** 24’3 “ 26’3 ” 24’7 “ 27’11 ” GA 8521 GA 9032 17′ 28’10 ” GA 15021 30’10 “ 48’3 ” Red text in table denotes new product introduction for 2011 *Varies with crop conditions, includes windrow **GA rotary rakes are available in trailed and mounted models ***Largest working width is with a double windrow Detailed features and specifications for a proposed machine are developed by product management to address the customers’ needs. A product development team is created to get input from all functional areas of the Company to ensure that all new product concerns are addressed. original The Kuhn SpeedRake® continues to set the standard for innovation, durability and performance in the wheel rake class. These rakes provide high capacity, uniform crop flow, clean raking and neatly-formed windrows to speed baling. With unmatched transportability and maneuverability, they help save time and maximize harvest productivity. lower case thinner border lower case Garamond lower case thinner border SR 600 Generation II High-Capacity, SpeedRake Upper case Garamond Tight turns made easy SR 300 High-Capacity, Carted SpeedRake Upper case Garamond Independent rake wheel flotation MODEL SR 108 SR 110 SR 112 SR 310 WORKING WIDTH* 15’10 “ 18’10 ” 16’11 “ 21’2 ” 18’9 ” 23’4 ” 17’6 “ 20’10 ” MODEL WORKING WIDTH* SR 312 20’10 “ 24’2 ” SR 614 GII 28′ SR 616 GII 32′ Red text in table denotes new product introduction for 2011 *Varies with crop conditions, includes windrow SR 110 Carted SpeedRake Engineers take the specifications and progressively develop a 3D Computer Aided Design (CAD) model of the new machine, shaping the overall look and function of the unit. The engineers design 3D CAD models of the individual parts, combine them into sub-assemblies, and eventually into the final overall assembly model. Kuhn produces quality rotary tedders that reduceoriginal drying time. Uniformly-tedded hay dries faster, which preserves valuable nutrients and allows you to harvest sooner.

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 1 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 1 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 2 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 2 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 3 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 3 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 4 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 4 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 5 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 5 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 6 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 6 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 7 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 7 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 8 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 8 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 9 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 9 of 16 Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 10 of 16

Kuhn MM 300 MM 900 Merge Maxx GA 9032 SR 600 GF 10802 VT 180 GMD 3550 TL PSC 181 8124 890 Agricultural Catalog - 10 of 16