From inside (document excerpt):

Disc mower GMD LIFT-CONTROL® Series WHEN YOUR PEACE OF MIND COUNTS ON QUALITY AND PRODUCTIVITY! KUHN LIFT-CONTROL® DISC MOWERS Harvesting high quality fodder is, more than ever, the corner stone of any efficient, profitable, long-lasting farm today. Mowing is the first operation in the harvesting sequence and is, therefore, particularly important. Apart from choosing the optimal stage of plant growth at mowing time, everyone knows that it is an intense and stressful time: a large area has to be mown in a very short time to assure uniform drying of all the crop and limit risks of changing weather conditions.

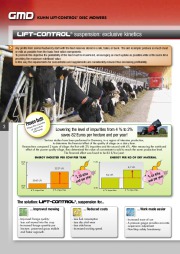

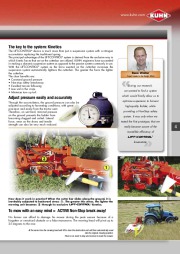

At such times, it is important to be able to count on the reliability of KUHN mowers. The presence of impurities in the fodder is a major detriment, particularly for silage making. Any energy lost in the field will be a source of lost productivity and must be compensated for with concentrates. KUHN has combined all its force and experience to propose a device which is unique on the market: the LIFT-CONTROL® suspension system. Results were not long in coming. Users discovered that the fodder had a higher nutrient value and a more appetizing appearance. Agricultural journals were quick to praise the benefits of this system. The GMD LIFT-CONTROL® system is now a market reference in terms of suspension and cutting quality. So don’t hesitate, you won’t be disappointed! KUHN offers solutions for mowing while meeting your requirements in terms of: Cost reductions Good practices www.kuhn.com Comfort Quality of life Proximity Advice Peace of mind Services KUHN LIFT-CONTROL® DISC MOWERS ® suspension: exclusive kinetics Any profits from animal husbandry start with the feed reserves stored in a silo, bales, or bunk. The aim is simple: produce as much meat or milk as possible from the basic feed ration components. To promote this objective the palatability of the feed must be maximized, encouraging as much uptake as possible while at the same time providing the maximum nutritional value. In this way the requirements for concentrates and supplements are considerably reduced thus increasing profitability. 3 ts en fac Prov er amb s Ch re m ser-E ultu We f agric y) o man r (Ge Lowering the level of impurities from 4 % to 2% saves 82 Euros per hectare and per year! Serious studies have been performed in Germany, in a region of intensive production, to determine the financial effect of the quality of silage on a dairy farm. Researchers compared 2 types of silage: the first with 2% impurities and the second with 4%. After measuring the nutritional effect of the poorer quality silage, they determined the value of concentrate to add to reach the same production level. The financial effect was found to be 82 /ha/year! ENERGY INGESTED PER COW PER YEAR 2400 UFL 9 UFL ENERGY PER KG OF DRY MATERIAL 2227 UFL 8,7 UFL 2060 UFL 2000 UFL /ha + 38 r year pe and 8 UFL 8,4 UFL /ha + 44 r year pe and 2 % impurities 4 % impurities 2 % impurities 4 % impurities The solution:. Improved mowing – Improved forage quality: less soil moved into the crop – Increased forage quantity per hectare: preserved grass stubble and faster regrowth. ® , suspension for.. Reduced costs. Work made easier – Increased ease of use – A pressure gauge provides accurate suspension adjustment – Non-Stop safety breakaway. – Less fuel consumption – Less disc skid wear – Less side forces – Increased working speed. www.kuhn.com The key to the system: Kinetics The LIFT-CONTROL® device is much more than just a suspension system with a nitrogen accumulator replacing the traditional spring. The principal advantage of the LIFT-CONTROL® system is derived from the exclusive way in which kinetic forces that act on the cutterbar are utilized. KUHN engineers have succeeded in making a dynamic suspension system as opposed to the passive system commonly in use. With the LIFT-CONTROL® system as the force exerted on the cutterbar increases the suspension system automatically lightens the cutterbar.

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 1 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 1 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 2 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 2 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 3 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 3 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 4 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 4 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 5 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 5 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 6 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 6 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 7 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 7 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 8 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 8 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 9 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 9 of 16 Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 10 of 16

Kuhn Disc Mower GMD LIFT CONTROL Series Agricultural Catalog - 10 of 16