From inside (document excerpt):

FC Mower Conditioner ALTERNA 400 / ALTERNA 500-500 R H AY M A K I N G AT I T S B E S T ! KUHN trailed Mower Conditioners KUHN ALTERNA discs mowers feature a working width, cutterbar shape and swath delivery that provide all assets for crop harvesting, and in particular for silage making. KUHN offers solutions for mowing while meeting your requirements in terms of: COST REDUCTIONS GOOD PRACTICES COMFORT – QUALITY OF LIFE PROXIMITY – ADVICES PEACE OF MIND – SERVICES Mower Conditioners ALTERNA 400/500/500 R High working capacity controlled with ease, precision and flexibility 3 Centre pivot flexibility and performance, enhanced temps use of Kuhn’s Gyrodine hitch, · La fauche en allers-retours, sans efforts ni perte deby the : depuis le poste de conduite, for vous positionnerez alternativement la machine à droite ou à gauche, unsurpassed manoeuvrability.

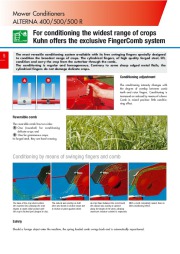

® · La significantly reduces the amountferaheadland required for turning while en the same time This tête pivotante GIRODYNE vous of oublier les fastidieuses manoeuvres at fourrière, · Laissez-vous impressionner par la précision des commandes et la maniabilité de la machine, increasing productivity and operator efficiency. ALTERNA: Designed to increase field productivity! Mowing to the left Mowing to the right All for crop quality Large wheels On wet soils, appreciate the high flotation advantages of dual wheels on Alterna 500, or the super-single wheels on the Alterna 400. The risk of ruts in difficult conditions is minimized. 4 Flexibility and ground contour adaptation Despite the wide cutting width of the Alterna, these machines are well suited for following rolling terrain. Benefits include: – Preservation of grass stubble – Reduced power requirements – Less skid wear Single point suspension adjustment The ALTERNA suspension is ensured by suspension links with ball joints and centrally adjusted suspension springs. Swath width adjustable from 1.90 to 2.90 m / 6’2” to 9’6” Double swaths ideally suited for 3 m / 10′ pick up attachments Double swaths, separated by up to 80 cm / 2’7 ” depending on the swath width setting, allow the tractor to operate without driving on the cut crop. – Complete and even drying is assured as significantly more crop is exposed to air and sunlight than if only a narrow single windrow is produced that is not run over by the tractor. – With an overall width adjustable from 1.90 to 2.90 m/ 6’2 ” to 9’6 “, they are perfectly adapted to 3 m pick-ups. The crop volume handled being distributed on two swaths, the harvesting machine is evenly fed. Mower Conditioners ALTERNA 400/500/500 R For conditioning the widest range of crops Kuhn offers the exclusive FingerComb system 5 The most versatile conditioning system available with its free swinging fingers specially designed to condition the broadest range of crops. The cylindrical fingers, of high quality forged steel, lift, condition and carry the crop from the cutterbar through the comb. The conditioning is regular and homogeneous. Contrary to some sharp edged metal flails, the cylindrical fingers do not damage delicate crops. Conditioning adjustment A B The conditioning intensity changes with the degree of overlap between comb teeth and rotor fingers. Conditioning is increased or reduced by means of a lever. Comb in raised position: little conditioning effect. Reversible comb The reversible comb has two sides: A One (rounded) for conditioning delicate crops and B One for gramineous crops. In forged steel, they are hard-wearing Conditioning by means of swinging fingers and comb The base of the crop stems enters the machine first, allowing the rotor fingers to make initial contact with the crop’s thickest part (longest to dry). The natural wax coating on both stem and leaves is broken down due to friction of plant against shield. As crop flows between the comb teeth, With a comb completely raised, there is the natural wax coating is opened little conditioning effect. along the length of the stem

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 1 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 1 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 2 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 2 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 3 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 3 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 4 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 4 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 5 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 5 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 6 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 6 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 7 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 7 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 8 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 8 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 9 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 9 of 12 Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 10 of 12

Kuhn FC Mower Conditioner ALTERNA 400 ALTERNA 500 500 Agricultural Catalog - 10 of 12