From inside (document excerpt):

GF Gyrotedders, 102 and 1002 series EF F EC TIVE TED D IN G GF GYROTEDDERS GF SERIES 1002 Harvesting high quality fodder is rarely due to chance. Every detail is important. Every operation must be coordinated and optimised, taking into account the specificities of the fodder, relief, climate, areas to harvest and storage method. Every extra nutrient energy source given to animals in their basic fodder helps reduce the quantity of concentrate required in the ration.

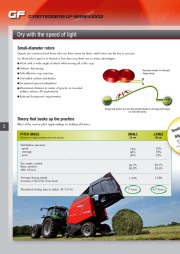

Tedding is a key link in the harvesting chain because it accelerates drying speed. The aim is simple: it reduces the drying time to preserve the energy value of the fodder and limit weatherrelated risks. KUHN offers the most complete and adaptive range of tedders available for the market. KUHN tedders are not only designed to treat the crop properly but to be reliable as well. Farms that beat the weather and the odds run with Kuhn machinery. KUHN offers solutions for tedding while meeting your requirements in terms of : Cost reductions Good practices www.kuhn.com Comfort Quality of life Proximity Advice Peace of mind Services GF GYROTEDDERS GF SERIES 1002 GF 102 series: 100% efficiency, 0% superfluous Cost control is an essential issue on many farms. With the 102 series range, KUHN provides you with tedders which have all the features required for high-quality tedding without too much sophistication. On the other hand, no need to worry, they are still KUHN machines: no short-cuts have been made in reliability or longevity. They are part of our basic commitment. 3 GF 422 GF 502 Simplicity and performance At work, the rotors faithfully follow the tractor, thanks to their pivoting headstock. Activate the hydraulic valve and the tractor lift raises the rotors for transport. In this position, the rotors are automatically centred and locked; fast and safe transport. 4 Individual oblique positioning Each wheel can easily be adjusted obliquely and without tools for accurate tedding along edges, without losing or wasting precious forage. GF 642 GF GYROTEDDERS GF SERIES 1002 Dry with the speed of light Small-diameter rotors Experts are convinced and those who use them swear by them: small rotors are the key to success! For those who’s goal is to harvest a first class crop there are so many advantages: Work with a wide angle of attack while turning all of the crop Uniform, fast drying Fully effective crop inversion Unrivalled uniform distribution Exceptional ground adaptation Minimimum distance to center of gravity on mounted tedders reduces lift requirements Reduced horsepower requirements. Improved overlap for thorough forage raking Forage fully turned over and well aerated thanks to the large pitch angle for improved drying Theory that backs up the practice 5 Effect of the various pitch angle settings on tedding efficiency. PITCH ANGLE Difference in height between rotor front and rear SMALL 24 cm LARGE 40 cm ll Sma Big Distribution precision – good – average – poor Dry matter content Basic product after 4 hours . 20,7% 26,0% 20,7% 28,6% 14% 46% 39% 29% 39% 32% 33% fo sma C Average drying speed Increase in the D.M./hour level . 1,33% 1,98% Theoretical drying time to obtain 30 % D.M. . 7 hours 4,7 hours www.kuhn.com Legends in the making DIGIDRIVE® When a Kuhn engineer came up with this drive coupling we knew that this would change the rotary tedder as it was then known. Indeed, this patented design made it possible to reliably drive a large number of rotors yet fold them with unrivalled compactness, all with virtually no maintenance or repairs. Since Digidrive’s inception nearly 20 years have passed and more than 150,000 tedders are now at work across the land tedding hay with unmatched reliablity. DIGIDRIVE 6 THE ORIGINAL L’original Minimized maintenance

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 1 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 1 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 2 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 2 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 3 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 3 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 4 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 4 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 5 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 5 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 6 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 6 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 7 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 7 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 8 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 8 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 9 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 9 of 30 Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 10 of 30

Kuhn GF Gyrotedders 102 1002 Series EF F EC Agricultural Catalog - 10 of 30