From inside (document excerpt):

5100 Vertical Maxx® Side-Discharge Twin-Auger TMR Mixers 738 1125 Cubic Feet WORLD-WIDE LEADER IN TMR MIXERS Vertical Maxx Mixers ® 5173 51100 5100 SIDE DISCHARGE SERIES The 5173, 5185 and 51100 high-capacity vertical mixers are designed for commercial dairy or beef operations that have much higher feeding cycles than small to mid-size farms. The Vertical Maxx vertical mixer is versatile to process and mix the widest variety of feedstuffs, including round bales, square bales, baleage, short-cut forages, small grains, concentrates and other difficult material.

Agricultural Equipment Manual Free Download. Lawn Mowers Specs. Power Harvesting Machinery Free Specification Download PDF.

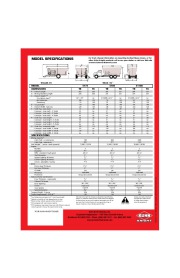

The Vertical Maxx features a twin-auger design, simple Bull Gear Drive system, side delivery and low loading height. The Vertical Maxx will provide your animals with a quality ration with day-to-day dependability needed for your commercial operation. Replaceable Hay-cutting Knives Several types of two-position hay-cutting knives are available for different applications and may be set out to improve processing or set in to reduce horsepower. TWIN-AUGER DESIGN Vertical Maxx features The twin-auger design allows for quick and efficient hay processing as well as a fast and thorough cleanout. Three adjustable high/low position hay stops provide different settings in high-hay rations for faster and thorough hay processing. The linkage arm for the discharge door allows for a larger door opening to maximize feed flow, even in high-hay rations. The unique, automatic-resetting torque disconnect clutch protects the mixer drive from shock when processing hay and other heavy loads. Simple slide tray, 4-auger, and chain and slat discharge options are available to match any feeding application or ration type. Curved Auger Kickers Kickers are bent back so feed efficiently charges the door to provide a more even discharge, faster unloading and better feed movement during mixing. Discharge Door Locations Right, left or dual doors are available to meet any feeding need and a rear door option is specifically designed to easily discharge premix loads into a commodity bay. Large Side Discharge Door The side discharge reduces the overall length of the unit and eliminates the cost of maintaining front-unloading cross conveyors. Key Features! World-Wide Leader in TMR Mixers MODEL SPECIFICATIONS For truck chassis information on mounting Vertical Maxx mixers, or for other Kuhn Knight products, call or see your dealer or visit our Web site at www.kuhnnorthamerica.com TRAILER -TR TRUCK -TK 1 MODEL DIMENSIONS A – Overall Length B – Mixing Chamber Length C – Overall Height 1, 2 – Tire Option Used 2 – No Extensions – Extensions D – Tread Width 2 E – Overall Width – tub only F – Slide Tray – max reach – Conveyor – max reach – 2′ chute – Conveyor – max reach – 3′ chute – Conveyor – max reach – 4′ chute G – Slide Tray – max height – Conveyor – max height – 2′ chute – Conveyor – max height – 3′ chute – Conveyor – max height – 4′ chute H – Slide Tray – transport width – Conveyor – max width – 2′ chute – Conveyor – max width.

Kuhn Knight 5100 Vertical Maxx Side Discharge Twin Auger TMR Mixers 738 1125 Cubic Feet Agricultural Catalog - 1 of 3

Kuhn Knight 5100 Vertical Maxx Side Discharge Twin Auger TMR Mixers 738 1125 Cubic Feet Agricultural Catalog - 1 of 3 Kuhn Knight 5100 Vertical Maxx Side Discharge Twin Auger TMR Mixers 738 1125 Cubic Feet Agricultural Catalog - 2 of 3

Kuhn Knight 5100 Vertical Maxx Side Discharge Twin Auger TMR Mixers 738 1125 Cubic Feet Agricultural Catalog - 2 of 3 Kuhn Knight 5100 Vertical Maxx Side Discharge Twin Auger TMR Mixers 738 1125 Cubic Feet Agricultural Catalog - 3 of 3

Kuhn Knight 5100 Vertical Maxx Side Discharge Twin Auger TMR Mixers 738 1125 Cubic Feet Agricultural Catalog - 3 of 3