From inside (document excerpt):

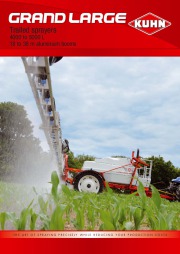

GRAND LARGE Trailed sprayers 4000 to 5000 L 18 to 38 m aluminium booms GRAND LARGE 4000 – 4500 – 50 The GRAND LARGE is suitable for cereal farms with needs that justify a simple, strong machine with a e A A s b if m o a h h high degree of technicality. This machine’s performance gives you more autonomy and helps reduce g g e nc.

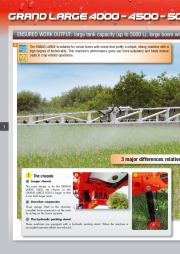

e n m p c costs in crop-related operations. o s o r p t ENSURED WORK OUTPUT: large tank capacity (up to 5000 L), large boom wid 1 3 major differences relative j e n 1 A The chassis Longer chassis B C The same design as for the GRAND LARGE 3200, the chassis on the GRAND LARGE 5000 is longer so that it can hold larger tanks. B Drawbar suspension Three springs fitted to the drawbar complete boom suspension on the road by acting on the boom supports. C The hydraulic parking stand These machines are equipped with a hydraulic parking stand. When the machine is uncoupled operator efforts are reduced. 000 www.kuhn.com dths (up to 38 m) 2 e to the GRAND LARGE 3200 A D R 2 2 The tanks 3 The booms · The main tank With a capacity of 4000, 4500 and 5000 L, the polyester tank has a smooth internal coating. Cleaning is easy. · The rinsing tank Positioned over the centre of the main tank, with a capacity of 430 L, it: · helps balance the machine · is close to the filler openings: main tank and rinsing tank. The GRAND LARGE 5000 has an extra boom frame, compared with the GRAND LARGE 3200: the RHA from 32 to 38 m. This is equivalent to the RBA boom with larger dimensions. Tube 120×60 instead of 100×50 for example. Standard equipment on the GRAND LARGE 4000, 4500 or 5000 litre polyester tank with smooth internal finish, float gauge with indirect read-out, automatic drain valve, 430 L rinsing tank, 16 L hand -wash tank operating panel with multifunction valves, control by wide angle drive, pressure gauge with extended graduation, hydraulic parking stand, height-adjustable drawbar with suspension, suspended axle, built-in pump casing, fixed platform, ladder and guard rail, product incorporator on parallelogram with automatic tank rinse, 5 m filler hose, 2 tank flushing nozzles, pressurized filter before the flowmeter. TECHNICAL SPECIFICATIONS Tank capacity (L/gal) Actual tank capacity (L/gal) Boom widths (m/ft) Type of pump Regulation Length of axle-ring (m/ft) Adjustable track (m) Overall width (m/ft) Overall height (m) Unladen weight (kg/lbs) Standard tyres Optional tyres GRAND LARGE 4000 4500 5000/ 1056 -1188 – 1321 4470 – 4830 5250 / 1180 1276 – 1387 18 to 38 / 59′ to 124’6” Diaphragm PM 265 (265l/min) Centrifugal PC 700 DPME (DPS) or DPAE (RSB3 or REB3 or REB+) 5.00 / 16’4” 1.80 to 2.25 /5’9” to 7’4” 2.55/8’4” Depending on the height of the hitch and drawbar adjustment 2700 to 3500 /5940 to 7700 12.4×46 11.2×54 / 12.4×52 / 13.6×48 / 14.9×46 / 16.9×38 / 18.4×38 / 20.8×38 / 18.4×42 / 20.8×42 Dimensions and weights are for information only and may vary according to the machine configuration. Optional equipment To protect the environment, this leaflet is printed on chlorine-free paper. / Printed in France – GP 0006 GB – 10.09 – KUHN 2009 Filler flowmeter choice according to setting (independent for direct read-out or with buzzer or automatic stop), electronic gauge (with buzzer or automatic stop or rinse assistance), mixed setting, DPI box, flow-rate/pressure, electric rotating cleaner, 2nd tractor equipment (cable, power outlet and mounting console), air brakes, mudguard (width 380 or 480 mm), work lights, rotating light, external rinsing kit (automatic 15 m winder with spot spray gun), fairing under the chassis, storage box, steering axle, automatic shut off by GPS. KUHN Services*: benefits for maximum use and profitability of your equipment

Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 1 of 4

Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 1 of 4 Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 2 of 4

Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 2 of 4 Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 3 of 4

Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 3 of 4 Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 4 of 4

Kuhn GRAND LARGE Trailed Sprayers 4000 5000 L Agricultural Catalog - 4 of 4