From inside (document excerpt):

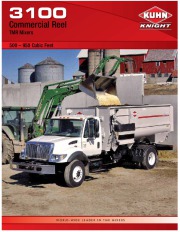

3100 Feedlot TMR Mixers Commercial Reel 500 950 Cubic Feet Innovative Reel and Auger Design GET THE COMMERCIAL REEL ADVANTAGE A more palatable ration Fast and gentle mix Less pressure means less HP required, less machine wear, less feed breakdown Effective hay-handling capability Dependable performance Front View THE REEL MIXING DESIGN The Commercial Reel Feedlot Series Mixer blends by gently lifting and tumbling fragile flaked corn and all other feed ingredients.

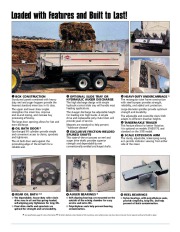

This produces a more palatable ration with fewer fines ensuring increased consumption and better weight gains. The gentle tumbling action of the large-diameter reel works together with the two side blending augers to produce an end-to-end and side-to-side mixing action. This unique combination ensures faster mixing and unloading times and a very thorough mix, even when mixing small batches. The reel design eliminates much of the force and pressure inherent to most other mixer designs. This results in lower horsepower requirements, reduced machine wear and less feed breakdown. The Commercial Reel can effectively handle ground and unprocessed hay. This allows you to get cattle on feed faster by incorporating hay in the ration to better stimulate rumen activity. This mixer is designed for commercial feedlot operators who need dependable performance. Superior mix quality, dependability and long life promote higher feed intake and weight gains, fewer equipment problems and lower overall ownership costs. REEL FEED MOVEMENT The large reel turns slowly, gently lifting material up into the two side blending augers. The upper auger moves material rearward, while the lower auger moves material forward and serves as the discharge auger. REEL CROSSBARS & WIPERS Poly wipers assist the reel and augers in mixing even the finest ingredients and ensure complete cleanout. Adjustable spring-loaded crossbars relieve excessive pressure. UPPER AUGER The higher-speed upper auger assists mixing by moving material rearward. This auger assures excellent end-to-end mixing and proper load leveling. LOWER GRAIN AUGER The lower auger mixes by moving material forward and provides a fast, steady feed flow to the discharge. Round knives may be added to pre-existing holes when processing small amounts of hay in finishing rations. Loaded with Features and Built to Last! 3 8 1 7 3 2 6 5 BOX CONSTRUCTION Sturdy end panels combined with heavyduty reel and auger hoppers provide the heaviest standard mixer box in it’s class. The upper and lower shear angles strengthen the mixer box, improve end-to-end mixing, and increase hay processing efficiency. The large door opening allows for fast and even discharge. OPTIONAL SLIDE TRAY OR HYDRAULIC AUGER DISCHARGE The high discharge design with simple hydraulic-control slide tray will handle most feeding applications. The 4-auger discharge has adjustable height for feeding into high bunks. A simple drive and replaceable poly chute liners will provide years of service. Magnets are standard to help prevent “hardware disease “. HEAVY-DUTY UNDERCARRIAGE A The rectangular tube frame construction with steel bumper provides strength, reliability, and added unit protection. Large-diameter spindles provide optimum strength and durability. The adjustable and reversible clevis hitch adapts to different drawbar heights. TANDEM-AXLE TRAILER This feature allows for better flotation. It is optional on models 3160/3170, and standard on the 3195 model. OIL BATH DOOR B Gas-charged lift cylinders provide simple and convenient access to chains, sprockets and tighteners. The oil bath door seals against the protruding edge of the oil bath for a reliable seal. EXCLUSIVE FRICTION-WELDED SPLINED SHAFTS This state-of-the-art process on reel and auger drive shafts provides superior strength and dependability over conventionally welded and keyed shafts. SCALE EXTENSION ARM The sturdy, adjustable, telescoping swing arm permits indicator viewing from either side of the mixer.

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 1 of 6

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 1 of 6 Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 2 of 6

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 2 of 6 Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 3 of 6

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 3 of 6 Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 4 of 6

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 4 of 6 Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 5 of 6

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 5 of 6 Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 6 of 6

Kuhn Knight 3100 Commercial Reel Feedlot TMR Mixers 500-950 Cubic Feet Agricultural Catalog - 6 of 6